Precision Manufacturing Converting Capabilities

Innovation Beyond the Norm

M&C offers the advantage of clear focus and specialized experience in each of the several markets we serve… Health Care, Automotive, Electronics, Renewable Energy and Building & Construction.

We believe exposure to cross-market innovation is a superior approach in cross-pollinating solutions and in providing superior quality without forcing customers into any solution other than the very best one for their specific requirement.

Within each market, our highly sophisticated converting technologies and precision manufacturing capabilities are tailored to specific market needs and directed by our vast experience.

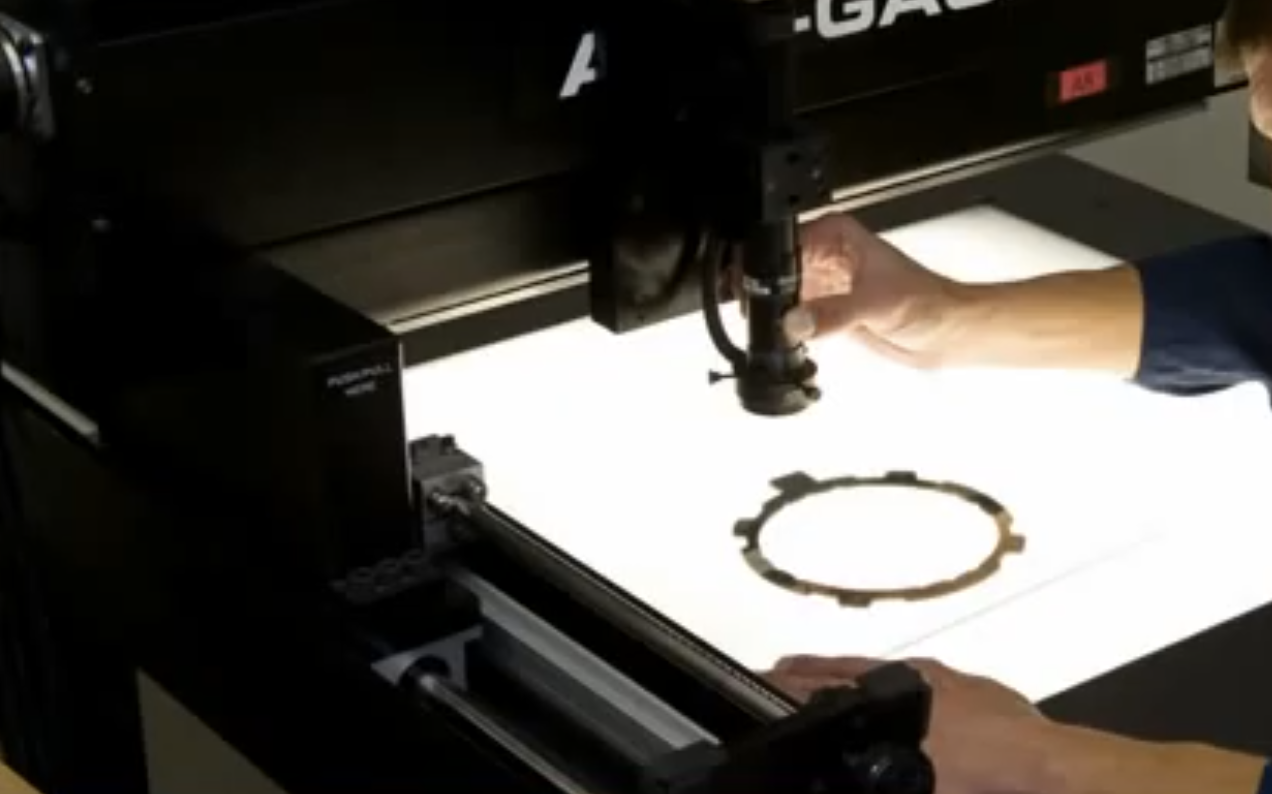

Inline laser die cutting

Inline laser die cutting utilizes a precision laser to achieve very small features with tight tolerances for high-speed production. M&C has laser systems to suit a variety of materials and production needs, including utilizing multiple stations combining traditional mechanical die cutting and laser die cutting.

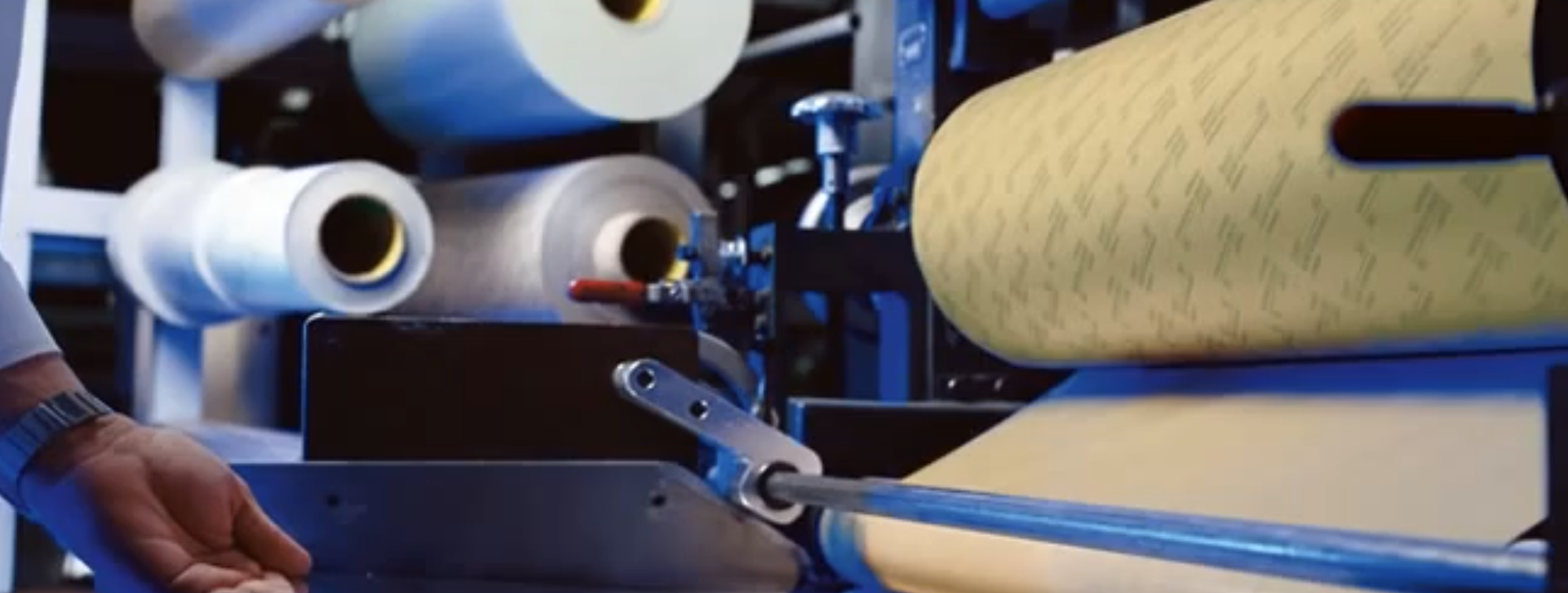

Rotary die cutting

Rotary die cutting uses precise engraved cylindrical dies for cutting roll-form materials. M&C has a diverse variety of rotary die cutting systems including laser die cutting, servo registration, vision registration, in-line vision inspection, servo tension-control, island placement, and more. M&C machines are capable of the tightest tolerances in the industry.

Flat-bed die cutting

Flat-bed die cutting produces large-format components from roll-form or sheet-form.

Laminating

For a wide range of materials and thicknesses supporting widths up to 60” and up to 14” in total layer thickness including zoned and patterned adhesives.

Spooling

Spooling optimizes material configuration on a single roll. M&C spooling systems can process a variety of materials and maximize efficiency for automated inline laminating processes.

Slitting

Slitting converts large production master rolls of materials into rolls of specified widths and lengths. These rolls are then used as a finished product or for further processing in the converting process.

Printing

M&C has a variety of printing capabilities including labels, instructions, flexographic plates, data matrices, consecutive numbering and hot stamping. These processes can be integrated into a later die cutting process for multi-step functional printed components.