Precision Converting Capabilities

With over 200 converting machines, we have the technology to bring your project from concept to production. M&C offers the advantage of clear focus and specialized experience in each of the markets we serve — healthcare, automotive, electronics, and building and construction. We use our exposure to innovations across markets to help enhance our customers’ solutions. We have perfected the art of providing superior quality without compromising our customers’ visions and goals.

Our processes and services consistently deliver

Enhanced product development

Improved processes & costs

Increased revenues

Improved productivity

Increased quality

Resolved manufacturing difficulties

Our Technologies & Processes

Within each market, our highly sophisticated converting technologies and precision manufacturing capabilities are tailored to specific market needs and directed by our vast experience.

Inline laser die cutting

Inline laser die cutting

Inline laser die cutting utilizes a precision laser to achieve very small features with tight tolerances for high-speed production. M&C has laser systems to suit a variety of materials and production needs, including utilizing multiple stations combining traditional mechanical die cutting and laser die cutting.Rotary die cutting

Rotary die cutting

Rotary die cutting uses precise engraved cylindrical dies for cutting roll-form materials. M&C has a diverse variety of rotary die cutting systems including laser die cutting, servo registration, vision registration, in-line vision inspection, servo tension-control, island placement, and more. M&C machines are capable of the tightest tolerances in the industry.Flat-bed die cutting

Flat-bed die cutting

Flat-bed die cutting produces large-format components from roll-form or sheet-form.Laminating

Laminating

For a wide range of materials and thicknesses supporting widths up to 60” and up to 14” in total layer thickness including zoned and patterned adhesives.Spooling

Spooling

Spooling optimizes material configuration on a single roll. M&C spooling systems can process a variety of materials and maximize efficiency for automated inline laminating processes.Slitting

Slitting

Slitting converts large production master rolls of materials into rolls of specified widths and lengths. These rolls are then used as a finished product or for further processing in the converting process.Printing

Printing

M&C has a variety of printing capabilities including labels, instructions, flexographic plates, data matrices, consecutive numbering and hot stamping. These processes can be integrated into a later die cutting process for multi-step functional printed components.Laser cutting

Laser cutting

Laser cutting is used for small quantity runs and can produce sample part without the need for a tool or die.Precision Manufacturing Converting Services

Beyond our portfolio of converting technologies, we offer support throughout the production process, including material selection, design exploration, prototyping and even assembly and packaging. Our industry-leading service capabilities are dedicated to ensuring production and the environment are optimized and controlled to meet the specific needs of each customer and application.

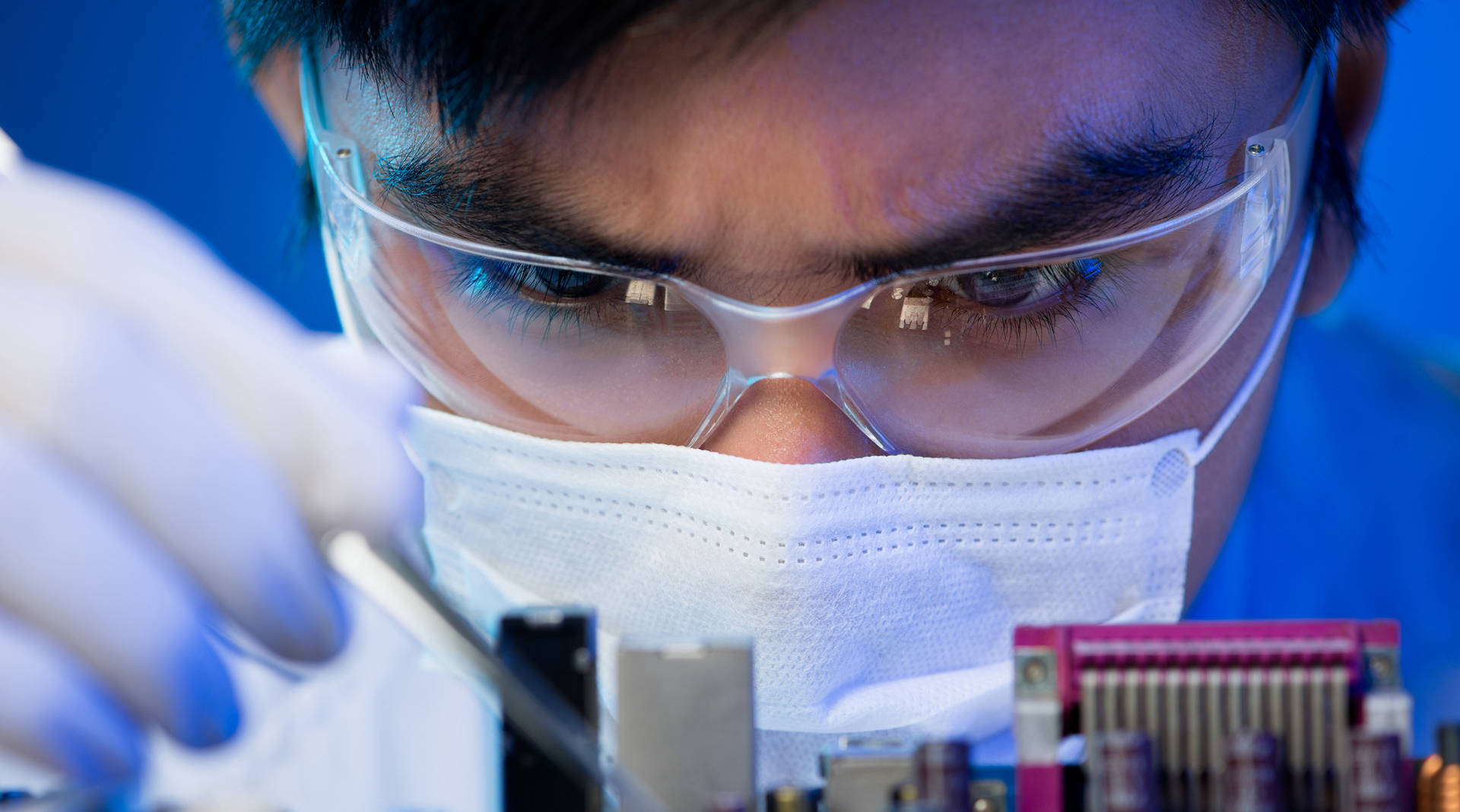

Clean Room and White Room Processing

M&C has multiple clean rooms and white room options to control and monitor environmental variables including particulates, temperature, and humidity to ensure product compliance. M&C is FDA registered and cGMP complaint.Prototyping

M&C experts utilize a variety of technologies which can be utilized for creating prototypes without the need for investment in mechanical tools. M&C accepts standard CAD formats.Packaging

Packaging options to suit each application include inline sealed options to finished product packaging. We offer assembly and packaging in strategic locations to serve our customers. M&C offers packaging in our white rooms and clean rooms. We are FDA registered and cGMP compliant.Assembly

M&C offers a wide-range of assembly options from partial to finished product assembly. We offer several assembly and packaging locations to serve our customers. M&C is FDA registered and cGMP complaint. As needed, M&C offers assembly in our white rooms and clean rooms.Sterilization

Complete sterilization solutions utilizing gamma irradiation, electron beam, and ethylene oxide technologies.Logistics/Inventory Management

Recognizing the global nature of our markets, M&C offers inventory management advantages for customers to manage raw material lead-times to reduce overall time to delivery. M&C has global and regional warehouses available to enable local support on a global scale. Our capitalization through ITW assures customers enjoy inventory on hand regardless of market segment.The value of choosing M&C Solutions

- Robust technology — over 200 cutting-edge converting machines

- Optimized use of raw materials

- Identification of additional components or elements to leverage

- Turnkey contract manufacturing partners

- Maximized product performance and market competitiveness

- Enhanced delivery to the market and supply chain management

Partner with us

Vision, innovation and entrepreneurial spirit have solidified M&C as a trusted manufacturer and partner for leading Fortune 500 companies. We use that experience and credibility to deliver for projects of all sizes using our Continuous Partner Involvement model. We are committed to offering you the support you need all the way through the product lifecycle.

As a global converter, contract manufacturer and fabricator of adhesive tapes, components and finished products, we look forward to learning more about your project.